But still, proper oral care is 70% of the device’s effectiveness. To keep this 70% intact, you need to follow simple rules regularly. First, be sure to completely remove your dentures before brushing your teeth.

Important! Remove the prosthesis, not the aba, because despite the screw structure, an ordinary person can damage the system when removing it; only a professional can do this. Secondly, use a soft brush and a gentle, non-sanding paste. Thirdly, thoroughly clean the denture itself, and it is advisable to use superfloss and an irrigator. And, of course, monitor the condition of artificial roots regularly! If you follow these simple rules, such a prosthesis will serve you for many years.

Multi-unit abutment

Key component of the All-on-4® treatment concept

Accuracy and ease of use from the developer

In 2000, Nobel Biocare developed the original Multi-unit abutment - at that time the first abutment of its type on the market. Since that time, it has become a recognized industry standard, and many manufacturers have attempted to copy its innovative design. The Multi-unit abutment differs from its analogues in those nuances that determine the success of prosthetics.

The Multi-unit abutment is designed for both full and partial restorations, and in particular for use in combination with the scientifically based and clinically proven All-on-4 ® treatment concept. 1-29

Carefully thought out design

- The short taper is ideal for limited interocclusal distances.

- The wide base of the abutment simplifies the installation of the prosthetic structure.

- For any gum type: straight and angled (17° and 30°) Multi-unit abutments have nine neck heights.

Simplicity and safety of operation

Each Multi-unit abutment comes with a pre-installed holder, making placement much easier. It also serves as a guide when checking the abutment angle.

Precision precision and aesthetics

Exceptionally accurate fit of fixed and semi-removable NobelProcera structures. A wide range of precision milled CAD/CAM designs, each carefully tested for compatibility and accurate fit with the Multi-unit abutment.

Multi-unit Plus Abutment

The Multi-unit Plus abutment for tapered implants takes the All-on-4 ® protocol to the next level. The Multi-unit Plus abutment is designed to significantly simplify and speed up temporary restorations.

Simplification of the temporary prosthetic protocol

The Temporary Snap Coping easily snaps onto the Multi-unit Plus Abutment and does not require the use of screws to secure the temporary restoration during try-in and preparation.

Save time in the clinic and laboratory

The new snap-on feature will help significantly reduce the time it takes to reline an existing prosthesis or create a new temporary structure.

Authenticity matters

A system is only as strong as its weakest link. The effectiveness of each individual component depends not only on its quality and design, but also on its interaction with the rest of the orthopedic system.

That's why we carry out tests and research both on the individual components and their interactions, and on the entire system they form.

Feedback from clinicians

Dr Rob Wain, UK

“I have been using Multi-unit abutments from Nobel Biocare for over ten years. I regularly use them both for All-on-4 ® treatment and for various clinical cases where it is necessary to compensate for the angle of the implant before installing a screw-retained prosthesis.

It is much more comfortable for both me and the patient to work at the soft tissue level, which allows me to perform prosthetics with a greater degree of confidence and safety. The long-term stability and success rates of the structures are excellent, and the easy access makes hygiene and care of the structure easier for the patient.”

Dr. Peter Wöhrle, USA

“The snap-on feature of the Multi-unit Plus abutment makes the integration of temporary copings into the temporary restoration much quicker and easier. This is important because treatment times are reduced, and even dentists with little experience can use this protocol with predictable results.”

Clinical cases

Dr. Paulo Maló, Portugal - All-on-4® Treatment Concept with NobelGuide

Clinical case:

female patient, 50 years old, completely edentulous, removable dentures on the upper and lower jaws installed more than 15 years ago.

Solution:

segmental rehabilitation of the upper jaw using fixed implant-supported structures and the All-on-4 ® treatment concept. The NobelGuide protocol (flapless technique) was used in the upper jaw, and the traditional All-on-4 ® flap technique was used in the lower jaw. High-precision NobelProcera implant-supported bridges were chosen as permanent structures in both the upper and lower jaws.

Dr. Rubén Davó, Spain – Complete rehabilitation for severe atrophy of the upper and lower jaw

Clinical case:

female patient, 60 years old, with severe bone resorption of the upper and lower jaw under a complete removable denture.

Solution:

For rehabilitation of the upper jaw, Brånemark System Zygoma and NobelReplace Tapered implants were used. The All-on-4 ® treatment concept was applied to the lower jaw. NobelProcera high-precision implant-supported bridges were chosen as the permanent structure in both the upper and lower jaws.

Literature

Multi-unit Abutment – Nobel Biocare

1. Malo P, de Araujo Nobre M, Lopes A. The use of computer-guided flapless implant surgery and four implants placed in immediate function to support a fixed denture: preliminary results after a mean follow-up period of thirteen months. J Prosthet Dent 2007;97(6 Suppl):26-34

2. Aparicio C, Perales, P, Rangert, B Tilted implants as an alternative to maxillary sinus grafting: a clinical, radiologic, and periotest study. Clin Implant Dent Related Res 2001; 3:39–49.

3. Abi Nader S, Eimar H, Momani, M. Plaque Accumulation Beneath Maxillary All-on-4 Implant-Supported Prostheses. Clin Implant Dent Relat Res 2014; epub ahead.

4. Agliardi E, Panigatti S, Clericò M, Villa C, Malò P. Immediate rehabilitation of the edentulous jaws with full fixed prostheses supported by four implants: interim results of a single cohort prospective study. Clin Oral Implants Res 2010; 21:459-655.

5. Antoun H, Belmon P, Cherfane P, Sitbon JM. Immediate loading of four or six implants in completely edentulous patients. Int J Periodontics Restorative Dent. 2012; 32(1):1-9.

6. Babbush C, Kutsko G, Brokloff J. The all-on-four immediate function treatment concept with NobelActive implants: a retrospective study. J Oral Implantol 2011;37:431-457.

7. Babbush C, Brokloff, J. A Single-Center Retrospective Analysis of 1001 Consecutively Placed NobelActive Implants. J Implant Dent 2012; 21(1): 28-35.

8. Baggi L, Pastore S, Di Girolamo M, Vairo G. Implant-bone load transfer mechanisms in complete-arch prostheses supported by four implants: A three-dimensional finite element approach, J Prosthet Dent 2013;109(1):9 -21

9. Butura CC, Galindo DF. Combined immediate loading of zygomatic and mandibular implants: a preliminary 2-year report of 19 patients. Int J Oral Maxillofac Implants 2014; 29(1): 22-29.

10. Butura CC, Galindo DF, Jensen OT. Mandibular all-on-four therapy using angled implants: a three-year clinical study of 857 implants in 219 jaws. Oral Maxillofac Surg Clin North Am 2011; 23(2): 289-300.

11. Cavalli N, Barbaro B, Spasari D. Tilted implants for full-arch rehabilitations in completely edentulous maxilla: a retrospective study. Int J Dent; ePub ahead 2012.

12. Francetti L, Agliardi E, Testori T. Immediate rehabilitation of the mandible with fixed full prosthesis supported by axial and tilted implants: interim results of a single cohort prospective study. Clin Implant Dent Relat Res 2008;10(4):255-263.

13. Francetti L, Romeo D, Corbella S, Taschieri S, Del Fabbro, M. Bone Level Changes Around Axial and Tilted Implants in Full-Arch Fixed Immediate Restorations. Interim Results of a Prospective Study. Clin Implant Dent Relat Res 2012; 14( 5):646-654.

14.Galindo DF, Butura CC. Immediately loaded mandibular fixed implant prostheses using the all-on-four protocol: a report of 183 consecutively treated patients with 1 year of function in definitive prostheses. Int J Oral Maxillofac Implants 2012; 27(3):628-633.

15. Gunaseelan R, Saravanakumar M, Hariharan R. Restoration of failing maxillary implant supported fixed prosthesis with cross arch splinted unilateral zygomatic implant: A Clinical Report. J Oral Implantol 2012;38(6):751-755.

16. Landazuri-Del Barrio RA, Cosyn J, De Paula WN, De Bruyn H, Marcantonio Jr E. A prospective study on implants installed with flapless-guided surgery using the all-on-four concept in the mandible. Clin Oral Implants Res 2013;24(4) 428-433.

17. Lopes A, Maló P, de Araújo Nobre M, Sanchez-Fernández E. The NobelGuide® All-on-4® Treatment Concept for Rehabilitation of Edentulous Jaws: A Prospective Report on Medium- and Long-Term Outcomes. Clin Implant Dent Relat Res 2014; 10.1111/cid.12260. .

18. Malo P, de Araujo Nobre M. A new approach for maxilla reconstruction. Eur J Oral Implantol 2009; 2(2):101-114.

19. Malo P, de Araujo Nobre M, Lopes A, Francischone C, Rigolizzo M. “All-on-4” Immediate-Function Concept for Completely Edentulous Maxillae: A Clinical Report on the Medium (3 Years) and Long-Term ( 5 Years) Outcomes. Clin Implant Dent Relat Res 2012;14 Suppl 1:139-150.

20. Malo P, de Araujo Nobre M, Lopes A, Moss SM, Molina GJ. A longitudinal study of the survival of All-on-4 implants in the mandible with up to 10 years of follow-up. J Am Dent Assoc 2011;142(3):310-320.

21. Malo P, de Sousa ST, De Araujo Nobre M. Individual Lithium Disilicate Crowns in a Full-Arch, Implant-Supported Rehabilitation: A Clinical Report. J Prosthodont 2014; ePub ahead.

22. Malo P, Nobre M, Lopes A, Francischone C, Rigolizzo, M. Three-year outcome of a retrospective cohort study on the rehabilitation of completely edentulous atrophic maxillae with immediately loaded extra-maxillary zygomatic implants. Eur J Oral Implantol 2012;5(1):37-46.

23. Malo P, Nobre M, Lopes A. Immediate Rehabilitation of Completely Edentulous Arches with a Four-Implant Prosthesis Concept in Difficult Conditions: An Open Cohort Study with a Mean Follow-up of 2 Years. Int J Oral Maxillofac Implants 2012;27(5):1177-1190.

24. Malo P, Rangert B, Nobre M. All-on-4 immediate-function concept with Branemark System implants for completely edentulous maxillae: a 1-year retrospective clinical study, Clin Implant Dent Relat Res 2005;7(Suppl 1): S88-S94, 2003-161

25. Mozzati M, Arata V, Gallesio G, Mussano F, Carossa S. Immediate Postextractive Dental Implant Placement with Immediate Loading on Four Implants for Mandibular-Full-Arch Rehabilitation: A Retrospective Analysis. Clin Implant Dent Relat Res 2013;15:332-40.

26. Puig CP. A retrospective study of edentulous patients rehabilitated according to the 'all-on-four' or the 'all-on-six' immediate function concept using flapless computer-guided implant surgery. Eur J Oral Implantol 2010;3(2):155-163.

27. Schroering R, Parrish K. Clinical protocol for rapid, graftless, four-implant restoration of the fully edentulous patient. Practical Procedures and Aesthetic Dentistry 2008; 29: supported by Nobel Biocare

28. Van Lierde, KM Browaeys H, Corthals P. Impact of fixed implant prosthetics using the 'all-on-four' treatment concept on speech intelligence, articulation and oromyofunctional behavior. Int J Oral Maxillofac Surg 2012; 41(12):1550–1557.

29. Weinstein R, Agliardi E, Fabbro MD, Romeo D, Francetti L. Immediate rehabilitation of the extremely atrophic mandible with fixed full-prosthesis supported by four implants. Clin Implant Dent Relat Res 2012;14:434-41.

Manufacturers

Two thousand companies produce implants and suprastructures, of which two hundred have their own factories, and only 62 companies have a closed production cycle. These include: Nobel Biocare (Switzerland), Alpha-Bio (Israel), Ankylos (Germany) and Astra Tech (Sweden).

Multi-unit abutments are available for almost all known systems and are a standard solution to non-standard prosthetic problems.

Nobel (Nobel) . The Nobel company produces suprastructures from highly biocompatible materials (titanium, zirconium, gold, and their alloys) using the latest technologies. The difference between Nobel products is super precise fit, excellent cosmetic results.

The innovative design of the original Multi-unit Nobel adapter is the recognized standard for partial and full dentures. Conditionally removable acrylic dentures are manufactured using patented NobelProcera technology based on scanning and 3D modeling. After calculations, we obtain the most accurate titanium frame and a multi-profile connecting element adapted to the patient’s jaw.

Features of abutments made using Nobel Procera technology:

- strength;

- accuracy;

- maintainability;

- aesthetics;

- long-term operation.

Alpha-Bio (Alpha-Bio) . They are made from biocompatible materials, have a practical design, and fit well to the gums. The main difference is a reliable connection and ease of installation. The hexagonal recess inside the metal root fits exactly into the hexagonal cone of the superstructure. A tight fit of the inner wall of the implant to the multiunit abutment is ensured, eliminating gaps and microcracks.

Ankylos (Ankylosis) . A special feature of German Ankylosis abutments is the TissueCare Connection, which moves the transition border closer to the center of the root. This reduces the load and eliminates loosening and breakage of the superstructure.

Ankylos implants are supplied in a sterile flask, each structural element is placed in a sealed package, the set contains a fixing screw and a holder. Ankylosis products are manufactured according to three-dimensional computer modeling. A unified fastening with an implant provides a free combination of orthopedic elements.

Dentium (Dentium) . The South Korean company began manufacturing implants and superstructures in 2000. Advantages of abutments:

- ease of installation;

- tight connection with the implant, eliminating the risk of infection;

- good stabilization due to tight fixation;

- excellent aesthetic indicators;

- time-tested quality.

Astra Tech (Astra Tech) . The Swedish company produces four types of permanent and temporary abutments for different clinical cases.

Features of Astra Tech multi-unit superstructures:

- Precise load distribution with self-centering Conical Seal Design.

- Sterility - Astra Tech implants are stored and transported in vacuum ampoules.

- The cone shape is a reliable insurance against displacements inside the structure.

- The absence of a central screw ensures tightness and prevents bacteria from entering the structure.

- The ability to grind allows you to adjust the size and shape of the structure to fit the jaw bone.

- Universality - thanks to the uniform diameter of the structural elements, each Astra Tech implant fits any Astra Tech abutment.

Dental implantation on multi-units

Implantation on Multi-units is a relatively new implant technology that facilitates and improves the installation of an orthopedic structure on titanium roots. Multi-unit is a multi-component abutment onto which the prosthetic system is fixed with a screw fastening. In contrast to the cement method of attachment, the prosthesis on Multi-units can be easily removed if correction or replacement is needed. Multi Unit prosthetics provide reliable, stable fixation. The depreciation of the prosthesis under chewing load and the risk of penetration of cement under the gums are eliminated.

Price

The cost of the multi-unit prosthetics service is due to the fact that only a qualified specialist can do this. Precise screw fixation and periodic maintenance of removable structures require deep knowledge and experience.

Installation of a metal-ceramic crown on an implant with a Multi-Unit abutment in 2022 costs from RUB 28,000. up to 45,000 rubles, and a zirconium crown can cost about 60,000 rubles. A complete bridge for one jaw will cost from 150,000 rubles. up to 500,000 rub. and higher.

What is Multi Unit

The ROOTT Multi-Unit implant and the Multi-Unit abutment are two different designs.

- Implant Multi-Unit ROOTT

One-piece monoblock implant with a flexible abutment (the root body and adapter form a single system). Such implants are used in one-stage protocols with immediate loading, when restoring a long-term dental defect - in the absence of 3 or more adjacent teeth. The orthopedic system is fixed 2-3 days after implantation of titanium roots. Thanks to the flexible adapter, the doctor adjusts the position of the prosthesis taking into account the characteristics of the patient’s bite and occlusion.

Multi-Unit Abutment

A separate element that is installed on a classic two-component implant after its complete osseointegration. It is used for both single and multiple restorations. Suitable for fixing a single crown or bridge.

Discomfort and possible complications after installation

A complication in the form of inflammation of soft tissues can occur after surgery to install implants, that is, they relate to the period after implantation. With the classical approach, the installation of supporting elements is carried out after complete engraftment of analogues of living roots, so there should be no complications here. If the elements are installed immediately, then unpleasant and dangerous consequences may arise.

You should consult a doctor if, a week after the operation, swelling of the soft tissues does not subside, there is increasing pain, and fluid/blood/pus is released from the gums around the operation area. All these manifestations can signal inflammation of the soft tissues and subsequent implant rejection. The reason is a violation of asepsis during procedures, poor oral hygiene during the rehabilitation period, infection of soft tissues due to a violation of the tightness of the connection due to unreliable fixation.

In the “implant-abutment-prosthesis” connection, each element of the system is equally important. So, if the implant and superstructure are installed correctly, but the artificial crown is made in violation of technical regulations and does not correspond to the characteristics of the patient’s bite, then because of this it can transfer an increased load to the implant, which will disable it.

Also, a frequent complication of incorrect installation is the formation of gingival growths around the superstructure, which greatly affects the aesthetics of the smile. If such a situation occurs, then you need to consult a doctor who will perform gum surgery and remove excess tissue.

%akc54%

Multi-unit implant system ROOTT

The ROOTT universal implantation system presents a line of one-component multi-unit implants for screw fastening of prosthetic structures.

- COMPRESSIVE M. Single-piece implant with multi-unit, standard diameter. Used for screw fixation of full and partial prosthetic structures.

- COMPRESSIVE MP . A one-piece multi-unit implant for installation in the pterygoid region, avoiding the sinus lift procedure.

- COMPRESSIVE MS . Long, narrow monoblock implant with multi-unit for installation in a narrow alveolar ridge. Used for multiple restorations in the anterior region.

All models of the COMPRESSIVE line with multi-units are characterized by:

- High initial and subsequent stability;

- reliable screw fixation;

- taking impressions at gum level;

- adjustable abutment angle;

- ability to be combined with other multi-unit implants.

Multiunit abutment

A classic abutment is a transitional element that combines an implant with an orthopedic structure (crown, bridge, complete denture) into a single system. The variability of adapters in shape, angle of inclination, material, manufacturer, installation method allows you to choose a superstructure for any type of prosthetics.

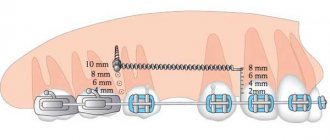

Unlike classic adapters, Multi-unit abutments are a multi-component design, consisting of several parts that are assembled into a single system during installation. Multi-unit abutments have different lengths, inclination angles, projection and neck heights. For ease of installation, systems are used on three orthopedic platforms - standard, wide, narrow. The fixation method is exclusively screw, which makes it possible to disassemble the structure in the future and replace a separate component.

The designs differ from classical analogues:

- short cone - solves the problem of limited interocclusal space;

- different neck height options - straight and angular nodes allow you to choose a model to suit the patient’s gums;

- different orthopedic platforms to simplify the installation process;

- pre-installation holder - acts as a guide when determining the desired angle of inclination.

The multi-unit abutment can be straight (with an inclination angle of up to 40°) and angular (with an inclination angle of up to 74° or up to 100 ⁰), to compensate for the angle of divergence between the axis of the artificial root and the orthopedic structure. The angle of inclination of the cone when fixing the adapter with a crown is from 5° to 35°.

Specifications

Some of the distinctive features that set MultiUnit models apart from alternative options include:

- Use of fixation technology on hexagonal-cone elements;

- Availability of a wide range of models with variable parameters;

- The use of an internal hexagon, which increases the accuracy of installation;

- The versatility of the elements, which determines the solution of various problems;

- The presence of a platform switching function that supports aesthetics;

- BioActive surface treatment for biocompatibility;

- Possibility of prosthetics in limited areas of the jaw row;

- Nine versions of cervical element height.

The standard package provided by the manufacturer includes a set of screwdrivers for different models of abutments, a titanium cap, an insert for gum formation, as well as auxiliary elements necessary for the implementation of the prosthetic protocol.

What is an abutment

An abutment is a transitional element that connects an implant and a dental prosthesis of any type - a dental bridge, a removable denture, a single crown. The threaded lower part is screwed into the implant, and the upper part serves as the basis for the crowns. It is placed only after the implant has successfully implanted in the bone.

Abutment translated from English means “support”. There should be no gaps between the implant and the prosthesis when connecting. Otherwise, there is a high probability of bacteria accumulation - and they can cause tissue inflammation, which will lead to implant rejection.

Types of implant-abutment connection

Companies producing implant products are constantly looking for new solutions so that their dental systems stand out from competitors, are liked by patients and dentists, and have an eternal service life.

It has long been proven that the connection plays an important role and affects the service life of the entire system. Therefore, manufacturers are trying to improve the types of connections or acquire the rights to successful solutions from premium segment implantology companies. Let's take a closer look at the most common types of connections.

Internal hexagon

The most commonly used type of connection in implantology today is an internal hexagon. It is worth noting that there can be more or fewer faces - 3, 4 or even 8 (it all depends on the manufacturer). How does an internal hex connection work? Imagine that the lower part of the superstructure is made in the form of a kind of “nut” with 6 edges, and inside the implant there is a special groove that has exactly the same outline. The two elements are connected to each other in one of six positions - as required by the treatment conditions.

This type of connection is quite easy to work with, because... it simplifies fitting and installation and allows the use of individual superstructures. The presence of an internal hexagon allows you to achieve high strength indicators for the entire system and evenly distribute the load. The disadvantage is the presence of a technological gap between the components, which makes the connection leaky.

External hexagon

Here everything is exactly the opposite. The entrance hole of the implant from above is made in the form of an external hexagon; it is placed inside the superstructure, which is why the connecting part itself is on top of the artificial root. At the moment, the system is recognized as less reliable, which is why it is used less and less.

Conical and hexagonal connection system

The superstructure has a conical shape, tapering downwards, and at the very end is made in the form of a hexagon. And on the implant (or inside it) there is a special hexagonal hole where the superstructure is placed. A system of a combination of a cone and a hexagon can be with or without an anti-rotation effect (i.e., eliminates rotation), and is also divided into 2 types based on the location of fixation:

- external: a more problematic option, because there is a risk of parts moving,

- internal: the lower part of the superstructure is installed inside the implant, which ensures the reliability and tightness of their connection to each other. Here, the risk of system elements unwinding during operation is practically eliminated.

Straight conical or cylindrical connection

There is no fastening in the form of connecting screws and contact edges (both external and internal), and fixation occurs only due to the tight fit of the surfaces to each other. The lower part of the superstructure is made in the form of an inverted cone (like Astra Tech) or a cylinder (like Bicon).

The positive side of this type of fixation is the freedom of positioning on the implant. The disadvantages include the complexity of manufacturing - so that after installation there are no gaps between the connection elements.

Interesting fact! Nobel Biocare has an option that comes in the form of an internal three-channel connection. The original model is called Replace Platform Shift and is used in complex and aesthetically significant areas.

Monolithic system

When considering cast models, it was already noted that this type of implantation product is created in one piece even during the production process. Those. the implant is firmly welded to the abutment, and they cannot be separated. The key advantage of one-piece products is the absence of any gaps, which prevents the penetration of infection or physiological fluids into the implant. However, the negative side of limiting the use of monolithic models is that they are not suitable for every patient based on clinical characteristics.

Individual

Such abutments are developed to special order and adjusted to the individual characteristics of a particular patient. Their creation became possible thanks to the advent of advanced computer technologies. Using CAD/CAM, a sample of the future abutment is modeled, after which the design is created on a robotic machine. As a rule, such abutments are no longer made of metal, but of zirconium, and are used mainly for the restoration of front teeth. This is where aesthetics are most important.

Custom abutment

The price of such a product, of course, will be an order of magnitude higher, but it has practically no disadvantages. Only advantages: excellent fit, the ability to take into account all the nuances, reduced risk of inflammatory processes, adjustment to the gums, ideal aesthetics.

Classification of models - advantages and disadvantages of each type

In modern dentistry, high-quality solutions are created thanks to innovative technologies. Each implant manufacturer has product lines that include not only implants, but also superstructures, instruments, and biomaterials. Support elements can differ in size (diameter, length and height), angle of inclination, type of platform (narrow, standard and wide), shape, material and even installation method. Below we will consider in detail the different types of abutments.

Very often, doctors offer to install an abutment, which is produced by another company (for example, Korean), and is conditionally suitable for all implants. This option should be abandoned. The implant and superstructure that are installed on the patient must be original and come from the same manufacturer. Otherwise, they may not have perfect contact with each other - the gaps may be microscopic and completely invisible to the naked eye. But even this will be enough for the development of complications, up to complete rejection of the implants due to overload from the abutment and prosthesis.

Classic or stamped models

This is the most common option; in another way, such products are also called stamped, because. they are manufactured at all implant manufacturing plants exclusively for their own products. The models are universal, have a standard shape, and are created mainly from titanium, less often from alloys of other metals or zirconium dioxide. They differ in height, diameter, and tilt options relative to the root (20º–45º). Suitable for a large number of patients, have an affordable price, because... The production of such abutments is maximally optimized, thought out, load-tested and automated.

In general, it is standard products that are the most popular and optimal in all respects. They, of course, have their drawbacks, but, in fact, there are still no alternatives - individual systems are not at all aimed at long-term functioning (we will explain why below).

Disadvantages of traditional superstructures:

- Sometimes there are problems with aesthetics: such products are most often created from metal, which has a gray tint. Therefore, in the frontal area, the support can be seen through the thin veneering material of the crowns. In addition, over time, the gums will definitely sag, so the structure may become noticeable, or it will be visible through the gums (at the point of contact with the gum crown it will “darken”). However, this is an inevitable fact and the most important thing is to monitor hygiene and regularly visit a doctor to correct this situation,

- sometimes the standard model cannot be applied in complex situations: here you really have to develop an individual system. But this may only be relevant when restoring the front teeth and is not acceptable for the side teeth, which bear an increased chewing load.

- Sometimes problems may arise when fixing the prosthesis with cement: some models do not have a ledge at the base, so if the crown is attached with cement, the liquid material can simply “fill” the space around the installed implant. Especially if the doctor did not select the concentration or amount of the product correctly. If there is a ledge, then the cement remains exclusively above it (i.e., within the coronal part) and does not fall under the mucosa. In addition, screw-retained models are increasingly being used today as a more effective alternative (read more about this type below).

The success of using any elements of the system largely depends on the professionalism of the doctor. So, a specialist needs to correctly select the correct angle of inclination and size from all the options for standard “connectors”, because An adapter that is too large or, on the contrary, small, simply will not allow you to achieve high-quality prosthetics. It is also possible to overload the root, which can lead to failure of the entire system.

Models created individually for each patient

Such a detail is already created exclusively for the bite characteristics of a particular patient. To make it, after implantation of the implant, the doctor takes impressions, then a prototype of the future model is created, the information is scanned and, using 3D technologies and CAD/CAM equipment, the dental technician develops an individual support for the crown. Everything takes no more than one week, and the end result is a product that allows you to achieve fairly high aesthetic standards. Also, individual models have a small ledge, which prevents cement from getting under the gum when installing them.

Materials for creating individual superstructures:

- Zirconium dioxide: used even more often than titanium. When individualizing treatment, the emphasis is most often on aesthetics, and zirconium dioxide (like ceramics) is white. This means that the product will not show through the crown, will not cause the gums to turn blue at the point of contact with the mucous membrane, but at the same time will be characterized by increased strength and hypoallergenicity,

- titanium or its alloy with aluminum and vanadium: such a product can be partially lined with ceramics to improve aesthetics,

- ceramics: which can be given any shade,

- gold plating.

There is such a thing as a “zirconium abutment”. But here it is important to understand the differences between the two materials: zirconium is a metal, but zirconium dioxide is no longer. It is white in color and bioinert - it does not cause allergic reactions, is extremely durable and is even comparable in hardness to many metals.

At first glance, it may seem that individual superstructures are better than template ones. But that's not true. Custom ones are created in a regular dental laboratory rather than in a manufacturing plant. And the dental technician physically does not have the opportunity to conduct multiple tests for functional load, which means it is completely unclear what pressure the superstructures will ultimately be able to withstand. That is why this option is not suitable for the lateral teeth with which we chew.

Read on the topic: everything about individual abutments in one article - manufacturing features, advantages and disadvantages.

There is a similar question regarding implants - will such supports really correctly distribute pressure on the intraosseous part of the system? It is important to understand that at the factory all elements of the system undergo a huge number of tests. And if the question is only about aesthetics, then today almost all manufacturers produce supporting superstructures created from snow-white zirconium dioxide - these are not individual, but standard, i.e. template models.

Temporary structure

The temporary abutment is made of plastic, less often of titanium (cheap MIS[1] implants and premium Nobel models have these). It serves as a temporary adapter between the implant and the adaptation prosthesis, which is installed immediately after implantation of artificial roots. For wearing a crown or simply taking impressions. They can also be used for the period of fitting and correction of permanent prosthetic products. These models are lightweight, aesthetic, but at the same time quite durable and inexpensive.

Ball-shaped systems

At the top they have the shape of a sphere, for which special recesses are created in the inner part of the prosthesis. Suitable for installing conditionally removable and removable dentures. This form of fastening helps patients not to think about dentures falling out of their mouth at the most inopportune moment. But it is very short-lived and can quickly fail, since it is not designed for strong mechanical loads. After a few years, such supports are subject to natural wear and need to be replaced. Moreover, sometimes it is necessary to change not only the superstructure, but also the implant.

For conditionally removable prosthetics, some manufacturing companies supply superstructures that work using the Locator system. These are unique solutions that, compared to spherical systems, have a flat base and provide the patient with easy, reliable fixation and removal of dentures. Essentially they work like buttons. They are more wear-resistant and last several times longer than spherical ones.

Also, some manufacturers supply products of the OT Equator type for removable prosthetics on implants, which are miniature in size and coated with titanium nitride, which increases wear resistance.

Direct superstructures

Most of the models currently in use have exactly this structure. Straight products are made both with and without a shoulder; they can have different neck heights for connection to the implant - 1, 2, 3, 4 millimeters. Designed primarily for the restoration of anterior teeth located in the smile zone, where implants are inserted strictly vertically.

Corner models

They have a certain axis tilt (usually 17° or 30°), which allows the dental crown to be placed directly on the implant if it is installed at an angle. Most often, such abutments are used for complex dental implantation. As a rule, we are talking about lateral areas, in which, due to the anatomy and unevenness of bone tissue atrophy, it is necessary to find the optimal solution for implantation. Installation of implants into the bone at an angle is necessary in the following situations:

- to bypass the sinuses and nerves,

- to use the most dense and sterile tissues: for better fixation of implants, installation is carried out in the buttresses of the skull - thickenings or force lines of the maxillary and zygomatic bones.

Thus, with the help of angular support components, the doctor is able to align the position of the crown or prosthetic device itself - so that they look as beautiful as possible and are comfortable to use.

Dental implantation using the Osstem system = 18,500 rubles. until January 15, 2022!

All inclusive, treatment guaranteed!

Premium implants at an affordable price. Free consultation with an implantologist +7 (495) 215-52-31 or write to us

Multiunit-abas are designed for reliable fixation of crowns or any other prostheses using a screw fastening system. They are multi-component structures, and due to the presence of a screw, they allow you to secure a crown or prosthesis so that, if necessary, it can be easily removed without sawing the entire system. Such abutments can be either straight or angular - a specific model is used depending on the situation.

Cast system integral with the implant

Monolithic models, where the abutment is connected to the dental implant at the production stage, are called one-piece. Essentially, it is just a one-piece implant that has no boundaries between the abutment and the intraosseous part. This allows dental implantation to be performed in just one visit to the doctor, which significantly reduces treatment time and also minimizes tissue trauma. A single-component type of implant is used mainly for one-stage implantation protocols, which involve immediate loading with the prosthesis.

The International Implant Foundation, based on numerous studies, has concluded that one-piece implants significantly reduce the likelihood of developing peri-implantitis and inflammation of the soft tissue around them. Thanks to the tightness, there is no risk of gaps and crevices forming between the components, into which pathogenic bacteria and plaque can enter. The connecting thread of such implants does not weaken during operation.

In order to prevent peri-implantitis, experienced doctors advise choosing either one-piece implant models (important in complex clinical cases with generalized periodontitis or periodontal disease) or two-piece types of implants with a polished neck-apex. Also suitable are models that have a smooth antibacterial coating on which plaque will not accumulate.

Temporary

Such models are made of plastic and are designed to connect an artificial tooth root with a temporary fixed prosthesis at the stage of implant healing. Or for trying on future prostheses, as well as their modeling. They are quite light and do not interfere with the process of fusion of bone tissue with the implant body, while having good aesthetics and fairly high strength.

Temporary abutment

Alternative Methods

The absence of one or more adjacent teeth can be compensated for by:

- removable dentures;

- bridges provided that the supporting teeth are healthy;

- prosthetics on mini-implants.

Angled multi-unit abutment

It differs in that it has a certain angle of inclination. Such models are used in cases where implants are placed at an angle. Due to the fact that the abutments are inclined, it is possible to level the position of the prosthesis. In addition, they allow the use of screw fastening, where a screw is screwed into the implant - it is placed through the top of the crowns. This way the prosthesis is securely fixed, but can be removed if necessary.

Angled multi-unit abutment

Taking an impression of multi-component abutments

After making impressions of the implants with the gingival margin formed, individualization of standard transfers for the open tray follows. Otherwise, an accurate impression of the soft tissue in the implantation area will not be obtained.

Algorithm for taking an impression of a MultiUnit structure:

- Transfers are established and recorded on superstructures.

- Impression fluid is applied around the transfer with a syringe.

- Impression fluid is applied to a special impression tray.

- A spoon is inserted into the oral cavity.

- After the material has hardened, the spoon is removed from the mouth and the screws securing the transfers are removed.

- The resulting impression is sent to the laboratory, where abutment analogs are combined with transfers.

- The screw is screwed in.

- A model of the mouth is cast.

Titanium

One of the main properties of a titanium abutment is its incredible strength, which virtually eliminates cases of product fracture under any load. Also, the material is completely biocompatible with the human body. However, like the implant itself, titanium is also used for its manufacture. Ideal for dental prosthetics in the chewing area, it is able to withstand and redistribute strong mechanical loads.

Titanium abutment

Zirconium dioxide abutment

Zirconium is highly aesthetic, so the use of such abutments would be appropriate for connecting a metal implant and prosthesis in the smile area. The gums look as natural as possible, since they do not come into contact with metal, and therefore are not stained. In addition, white zirconium dioxide abutments are invisible even with ceramic veneering - this is how artificial teeth fully imitate natural teeth.

Zirconium dioxide abutment

How to care for abutments

Since the adapters are hidden under the crowns, there is no need to directly care for them. But hygienic procedures require both crowns and all the tissues that surround them. You can clean the denture with a soft brush 3–4 days after fixation. In the very first days, in order to avoid injury to the mucous membranes, careful baths of antibacterial solutions are recommended (it is important not to rinse so that the stitches do not come apart, but simply keep the product in your mouth). Additional antiseptic and anti-inflammatory agents can also be used as prescribed by a doctor. Oral hygiene must be carried out in full accordance with the dentist’s recommendations to avoid gum inflammation or peri-implantitis.

Heal former

It is installed only temporarily; you need to wear it for about two weeks at the final stage of implantation. It helps to form a beautiful, smooth and clear gum contour. They will be used if you are restoring teeth using two-stage implantation with delayed loading of the prosthesis. Once the implant has completely taken root, the gum is opened, and the plug protecting the artificial root is replaced with a former.

Heal former

For screw fixation

These are a special type of abutments that are used to secure crowns with screws. They can be either straight or inclined (multi-unit - we talked about them above). In this case, the elements are connected using small screws - they are screwed into the abutment through the top of the crowns. To prevent the “hats” from being visible, the chewing surface is covered with a thin layer of composite.

Abutment for screw fixation

This type of abutment is mainly used in situations where there is a need to remove dentures. For example, when using implantation methods with immediate loading, when dentures are placed immediately after implantation.

How does the installation work?

Multi-unit adapters are installed after the healing abutments are removed. Installation is preceded by determining the required height of the connecting element.

Installation protocol:

- Select a multi-unit for the appropriate platform.

- Position and install into the implant using the holder.

- Tighten the screw connection.

- Remove the holder by rotating counterclockwise.

- Final tightening of the screw with a screwdriver and a wrench with a dynamic force of 30 N/cm.

MultiUnit suprastructures are usually supplied with a torque wrench, holder and screwdriver.