The widespread introduction of casting technology into the practice of dental laboratories has allowed foundry specialists to make thin-walled and high-precision solid-cast crowns from metals and medical alloys, designed to eliminate obvious defects in the dentition.

Such prosthetic devices are widely used in modern dental practice to restore the natural anatomical shape of damaged teeth or as supporting and fixing elements for prosthetic structures.

Why are all-metal crowns losing their relevance?

Article navigation

- What is the product

- In what cases are such crowns installed?

- Arguments for and against cast structures

- What are the types of cast products?

- What materials are these crowns made from?

- How structures are produced and installed

- Approximate prices

- How to care for cast dentures

- FAQ

Question for a specialist

In Soviet times, crowns made of ordinary metal looked familiar, and gold crowns were considered chic. Today, the idea of aesthetics has changed, dentistry has stepped far forward, and many modern clinics have completely abandoned this type of prosthetics. However, solid metal crowns are still installed in a number of cases - mainly as a budget option for dentition restoration.

Read about what these structures are made of, as well as their improved types, in today’s article.

Disadvantages of using solid crowns

The negative features of dental prosthetics using solid crowns include:

- the need to grind down a relatively large layer of surface tissue of the teeth;

- high thermal conductivity of prosthetic devices (if the pulp of the abutment tooth is close, the patient may experience severe discomfort);

- excessive abrasion of antagonist teeth during constant contact with the surface of a solid crown.

In addition, the disadvantage of such prosthetic devices is their appearance: the color of metal crowns does not match the color of natural tooth enamel. It is for this reason that they are used only for prosthetics of chewing teeth that are not noticeable when smiling and talking.

Otherwise, solid crowns fully perform their assigned tasks and are rightfully considered one of the best prosthetic devices designed to hide dentition defects.

What is the product

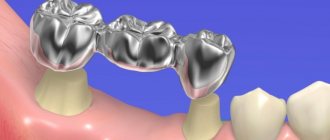

Solid dental crowns got their name based on their manufacturing technology - they are produced using a one-stage casting method in a mold. Models made from individual casts have the anatomical shape of the teeth of the future owner. In this way, it is possible to make both a single product and a bridge to replace several teeth - the technology allows you to do without soldering, which significantly saves time.

In what cases are such crowns installed?

Among the indications for installing solid crowns, experts in the field of dentistry and prosthetics identify the following clinical cases:

- the tooth is severely damaged - loss of dental tissue from 70%. In this case, filling does not make sense, since the pin with the light-polymer material simply will not hold,

- there are malocclusions, abnormalities in the location or shape of teeth,

- supports are needed to fix the bridge,

- pathological abrasion of enamel was diagnosed,

- the patient suffers from bruxism.

It should be noted that such structures can also be installed on the front teeth, but in this case the aesthetics of the smile will be seriously affected.

There are situations where solid, non-removable crowns can even harm the patient. Thus, among the contraindications to their installation are increased tooth sensitivity. The fact is that metal is a conductor of heat, so dental tissue will constantly experience temperature effects. As a result, inflammation of the pulp may develop.

Such designs are also not installed in patients who are allergic to metal. This is not a very common occurrence, but it should not be ignored. If a problem is identified, the dentist will suggest other options.

Increased wear of teeth on the opposite jaw is also a contraindication. Metal is much harder than dental tissue, so antagonistic elements will inevitably be subject to abrasion. If such a problem already exists, it will only get worse with the installation of cast products.

Don't know what type of prosthetics to choose?

We will help in the selection, advise where to read more information and compare types of prosthetics.

Consultation with an orthopedic doctor in Moscow clinics is free! Call now or request a call

Working hours: from 9:00 to 21:00 - seven days a week

Advantages and disadvantages

Such products have the following advantages:

- High quality and the ability to manufacture a design taking into account the individual characteristics of the patient’s jaw. Products are created individually for each tooth, they follow its shape and fit tightly to the gums.

- Durability and abrasion resistance. The structures are made from durable alloys that do not wear out for a long time; they are indicated for those who have pathological tooth wear. The products have a long service life.

- Possibility to do without deep preparation. Installation of solid cast structures involves grinding the teeth by only 0.8 mm.

The disadvantages of products of this type are the following qualities:

- lack of aesthetics,

- high thermal conductivity, which can cause discomfort when eating hot food or drinks.

Arguments for and against cast structures

In addition to the objective, today there is also a preconceived opinion about a solid-cast crown: that it is a product that has no advantages other than a low price. Of course this is not true. The main advantage of the design is durability: with proper installation and proper care, it can last more than 15 years. To present in detail the advantages of cast prostheses, let us compare them in a number of indicators with stamped ones (that is, created not individually, but from a template):

- tight fit: stamped structures are made from factory blanks, which are given an approximate shape using mechanical processing. It is impossible to install such a product tightly to the tooth surface - hence the ingress of food particles under the denture, the proliferation of bacteria, and the development of inflammatory processes. Cast products have high anatomical accuracy, so such problems are excluded,

- strength: the stamping is thin, therefore, under the influence of loads and chemical reactions in the oral cavity, it gradually collapses. After some time, a through hole is formed, opening access to infection. The result is the development of secondary caries, followed by pulpitis. The thickness of the solid crown is 0.3-0.5 mm. This is enough to successfully withstand both mechanical and chemical influences,

- safety: bridges from stamped elements are made by soldering. The connections are not very strong and often break - there is a high probability of injury. In addition, the products themselves and the solder have different compositions. This leads to the emergence of galvanic currents, which, in turn, cause irritation of the mucous membrane. Cast structures are made entirely from one alloy and do not require soldering, so such consequences do not occur.

Interesting! Stamped steel dental products are the oldest in their family. They were worn by many generations of Soviet citizens until the high toxicity of the composition, to which cadmium, beryllium, lead and other impurities harmful to health were added, was discovered. Nowadays such structures are made from a safer alloy, but in general stamping is carried out only in the deep provinces. Similar products have not been produced in any country except Russia for about 100 years.

Thanks to these properties of solid-cast crowns, both clasp and bridge systems using them will be more reliable. Surprisingly, cast metal prostheses have a number of advantages over metal-ceramic products that are popular today. The design is simpler, so it can be manufactured faster. In addition, cast metal is not at risk of chipping, as is the case with a ceramic coating. This product is also thinner than metal-ceramic, therefore, it requires less grinding of the teeth - as a result, they remain more viable.

The main disadvantage of metal prostheses is the lack of aesthetics, which today has acquired special importance. Therefore, such structures are placed only on chewing teeth, which are not very visible to others. But as soon as you laugh heartily, the alien metal will become noticeable.

“I’m 60 years old, and now I need to get my teeth done. Previously, I remember, there was no choice, but now there is nothing on offer. At first I wanted to install metal ones from casting - it doesn’t seem to be visible on the molars. Then I thought: I work as a teacher at school, constantly in public, I would still be embarrassed to talk and smile. I chose metal ceramics and I don’t regret it, I feel absolutely free.”

Vera Sergeevna, patient of one of the Moscow dental centers

Complex on 4 OSSTEM implants with delayed loading - from RUB 170,000.

Complex implantation Osstem (South Korea) with delayed loading after 4-6 months.

Guarantee for the doctor’s work - unlimited Call now or order a call

Opening hours: 24 hours a day - seven days a week

There are also more significant disadvantages. This is both a risk of developing allergies and a danger of damaging neighboring teeth, as well as those located on the opposite jaw - due to the high hardness of the metal. Therefore, if you are not too tight on funds, you should still consider more advanced prosthetic options. In particular, you can also choose a solid metal structure, but with ceramic lining (this will be discussed below).

What are the types of cast products?

Modern dentistry has significantly expanded the arsenal of metal casting products. Today the patient can choose designs:

- without spraying: they have a regular metal surface, polished to a shine. Aesthetics are reduced to zero,

- with spraying: to give a white color or a “gold” tint, the solid crown is treated with a special composition using vacuum plasma equipment,

- with partial cladding: ceramic or plastic linings are fixed to the front parts of the products. The teeth look natural, while the design will cost less than classic metal-ceramics,

- with full cladding: this option can no longer be called a product made only of metal. These are rather combined metal-ceramic crowns. Such designs are superior to all others in aesthetics and retain strength due to their metal base.

Spraying options are not suitable for everyone: compositions that are applied to the surface can irritate the oral mucosa. Therefore, to achieve aesthetics on a limited budget, it is still better to choose designs with front cladding, although they also have a drawback - cracks and chips often appear on the linings.

Kinds

A solid metal crown can be made from different materials.

Such products can be:

- metal with spraying,

- without spraying,

- with lining,

- combined bridge prosthesis.

The design without coating does not look very aesthetically pleasing; it is made of polished metal. It has a relatively low price, but not everyone is happy with it.

If aesthetics are important to the patient, then you should choose a crown with a coating that imitates gold. They look more attractive, but you should be careful when spraying: it can have a negative effect on the mucous membrane.

A one-piece crown with ceramic lining is perhaps the most aesthetic option of the three already presented - it has an overlay made of ceramic or plastic, which is located on its front surface. Of course, the pad also needs to be treated with care, because it is made of fragile materials, but if you follow the rules of care, it will last a long time.

A combined prosthesis is created from several metal-ceramic crowns that cover the smile area, and from solid polished crowns.

What materials are these crowns made from?

In the production of the structures under consideration, the following types of materials are mainly used:

- chromium-based alloys with the addition of nickel or cobalt: these are the most common materials characterized by increased strength - prostheses made from them are called carbide. They have the most affordable price, suitable for low-income people,

On a note! Today, one crown without coating will cost about 4 thousand rubles, with titanium nitride coating - about 5 thousand rubles. Ceramic cladding will increase the cost of the product to at least 7 thousand rubles. Treatment of identified pathologies, the work of a doctor, as well as the manufacture and installation of a temporary crown are paid separately.

- alloys of precious metals: solid gold dental crowns have a big advantage - they are biocompatible with the human body, and therefore do not cause allergic reactions. In its pure form, gold is not suitable for orthopedic purposes: it is too soft. Its alloys are used with copper, silver, palladium and even platinum. These compositions do not differ in color from pure metal, so this option in our time is only suitable for eccentric people. And the price is not affordable for everyone,

- alloys with titanium: structures lead in strength - it is 9-10 times higher than that of other products. Like gold, titanium is biologically compatible with natural tissues and does not have a harmful effect on the roots and adjacent teeth. However, such materials are extremely capricious, and the manufacturing process is labor-intensive. In addition, alloys have low adhesion to ceramics, so it will be difficult to create an aesthetic veneer.

It is better to entrust the choice of material for a crown to a specialist. The doctor will take into account all the features and nuances of the clinical picture, on the basis of which he can offer the most suitable option.

How structures are produced and installed

The creation and fixation of products is a standard dental procedure. Thus, the following clinical and laboratory stages of manufacturing solid crowns are distinguished:

- preparatory: through examination and examination, the doctor identifies existing diseases. If necessary, the tooth is treated and strengthened. Then it is prepared for a solid crown using a suitable method: using ultrasound or laser, tunnel or air-abrasive technology. After this, impressions are taken,

- modeling of a solid-cast crown: two models are made - a working one (of the dentition where the prosthesis will stand) and an auxiliary one (simulating the opposite row). Then they create a model - for this they use wax and plaster,

- product manufacturing: the process takes place in the laboratory. When the structure has already been cast, the specialist evaluates the quality of its execution and, at the request of the patient, covers it with ceramics. Then a fitting is carried out on a plaster copy of the patient’s tooth. If necessary, the product is adjusted.

Installation of a solid-cast crown is also performed in several stages. First, it is tried on the prepared tooth. If inaccuracies are identified, the design is returned for revision. Sometimes the product is temporarily fixed in the patient's mouth to determine whether there is any discomfort when chewing or an allergy to the alloy. If everything is in order, the prosthesis is secured with medical cement.

Classification:

By purpose:

- Restorative;

- Abutment (used in bridges ; they replace not only a defect within the coronal part of a tooth, but also a missing tooth or several teeth).

By design features:

- Full (cover the prepared stump from all sides), partial (three-quarter, half-crowns) leave the outer surface of the crown open;

- Telescopic (double; used in removable prosthetics, the first cone-shaped is fixed on the stump, the second, restoring the tooth, is part of the removable part and is put on the first).

According to the material used:

- Metal (noble or base alloys);

- Non-metallic (ceramics, zirconium dioxide, plastic, composite);

- Combined (metal-ceramics, metal-plastic).

By fixation method:

- Cemented (for prosthetics of natural teeth or on implants);

- Screw (used only for prosthetics on implants - artificial analogues of natural roots, strengthened inside the bone tissue of the jaws).

By service life:

- Permanent;

- Temporary - provisional (used at the stages of manufacturing the final ones to protect the stump from irritants, restore contacts with other teeth and for aesthetic purposes, including to form the contour of the gums ).

Approximate prices

The cost of prosthetics consists of several factors, including: an x-ray image - 1000 rubles, fixation of a temporary structure until the permanent one is ready - 2000 rubles, the cast crown itself - 6000 rubles. Of course, these are approximate prices that may vary depending on the level of prestige of the clinic and region of residence. Also, the selected type of metal has a direct impact on the formation of the cost of the product - gold structures are considered the most expensive, their price starts from 15-20 thousand rubles.

Only until 15.01 South Korean implant Osstem - from 18,500 rubles.

Hurry up to sign up for a free consultation and lock in promotional prices.

Call now or request a call

Opening hours: 24 hours a day - seven days a week